AI Technology Initially Designed for Mars Now Revolutionizes Earthly Assembly Lines

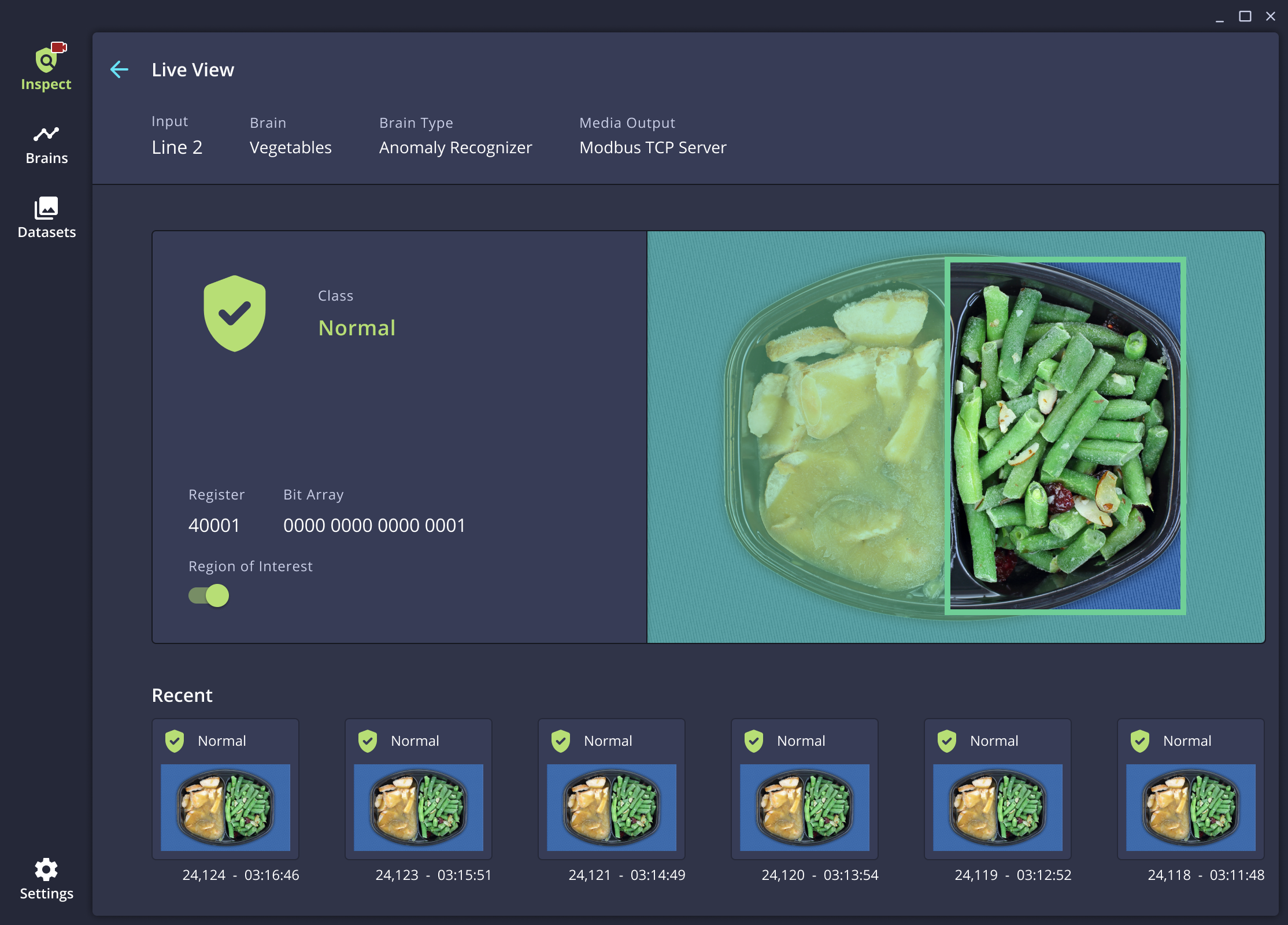

In a remarkable example of technology’s versatility, artificial intelligence (AI) software originally intended for Mars exploration is now being utilized to enhance the efficiency of assembly lines on Earth. This innovative transition highlights the adaptability of AI in addressing a variety of practical challenges. The advanced vision inspection software, developed by Neurala Inc., a forward-thinking AI company based in Boston, Massachusetts, is now being employed to monitor the quality of products on conveyor belts using existing cameras and computing devices, including smartphones.

Harnessing AI for Quality Assurance

Neurala’s AI software is designed to quickly adapt to the available processing power, a capability honed through extensive collaboration with NASA. This rapid adaptability allows the software to be integrated with minimal delay, enabling immediate vision inspection using existing hardware. According to Massimiliano Versace, the cofounder and CEO of Neurala, the software’s ability to function efficiently on a processor with a limited footprint was a key takeaway from their work with NASA. “By doing so, we enable vision inspection with whatever components are already available, deploying in minutes,” Versace explained. The company recognized that the manufacturing industry had a critical need for such technology, prompting them to pivot their focus towards this sector.

The Genesis of the Technology

The collaboration between Neurala and NASA began over a decade ago, under the auspices of the Small Business Technology Transfer (STTR) program. NASA was interested in developing “adaptive bio-inspired navigation for planetary exploration,” and Neurala, with its expertise in neural network AI modeled on the human brain, was well-positioned to meet this challenge. The project initially focused on creating a rover capable of independently navigating the Martian landscape. Neurala’s efforts were met with success, leading to the acquisition of STTR Phase II funding.

Further financial support from NASA’s Center Innovation Fund allowed Neurala to extend its technology to drone navigation and collision avoidance. A significant advantage of the Neurala software is its ability to operate on a small device within the vehicle itself, whether a rover or a drone. This feature eliminates the need to send signals to a decision-making center located elsewhere, thereby reducing delays and increasing operational efficiency. The same principle is now being applied to streamline quality control processes in manufacturing.

Advantages in the Manufacturing Sector

In the fast-paced environment of an assembly line, where hundreds of items may pass by every minute, conducting visual inspections for quality control can be daunting. By implementing Neurala’s AI software, manufacturers can overcome these challenges. The software’s capability to process data onsite, without relying on external computing resources, is particularly advantageous in this context. This approach not only accelerates the inspection process but also enhances accuracy and reliability.

Neurala’s technology is a prime example of how innovations initially conceived for space exploration can be repurposed to solve earthly problems. The transition from Mars rovers to assembly lines underscores the versatility and potential of AI in various domains. It also highlights the importance of collaboration between government agencies and private companies in fostering technological advancements that benefit society as a whole.

Implications and Future Prospects

The application of AI in quality assurance represents a significant leap forward for the manufacturing industry. By automating visual inspections, companies can reduce the likelihood of human error, improve product quality, and increase overall efficiency. This not only leads to cost savings but also enhances customer satisfaction by ensuring that products meet stringent quality standards.

Moreover, the use of AI in manufacturing is likely to drive further innovation. As technology continues to evolve, we can expect to see even more sophisticated applications that push the boundaries of what’s possible. For instance, AI could be integrated with other emerging technologies such as the Internet of Things (IoT) and big data analytics to create smart factories that operate with unprecedented levels of efficiency and precision.

Broader Impact on the Industry

The successful adaptation of Neurala’s AI software from space exploration to manufacturing serves as an inspiring case study for other industries. It demonstrates the potential for cross-industry innovation and the value of leveraging existing technologies in new and creative ways. As more companies recognize the benefits of AI, we can anticipate a growing demand for similar solutions across different sectors, from healthcare to finance to logistics.

Furthermore, the partnership between NASA and Neurala exemplifies the positive outcomes that can result from collaboration between public institutions and private enterprises. By working together, these entities can pool their resources and expertise to develop cutting-edge solutions that address complex challenges and drive progress in various fields.

Conclusion: A New Era of AI-Driven Innovation

The journey of Neurala’s AI technology from Mars to the manufacturing floor is a testament to the transformative power of artificial intelligence. It illustrates how innovative solutions can transcend their original purpose to deliver tangible benefits in unexpected areas. As industries continue to embrace AI, we can look forward to a future where technology plays an increasingly central role in shaping the way we live and work.

In conclusion, the integration of AI in manufacturing is not just a technological advancement; it is a catalyst for change, promising to revolutionize the way we produce goods and ensure quality. As we witness this new era of AI-driven innovation, it is clear that the possibilities are limitless, and the impact on society will be profound.

For more Information, Refer to this article.