Teamwork at the Heart of NASA’s Moon Rocket Engineering

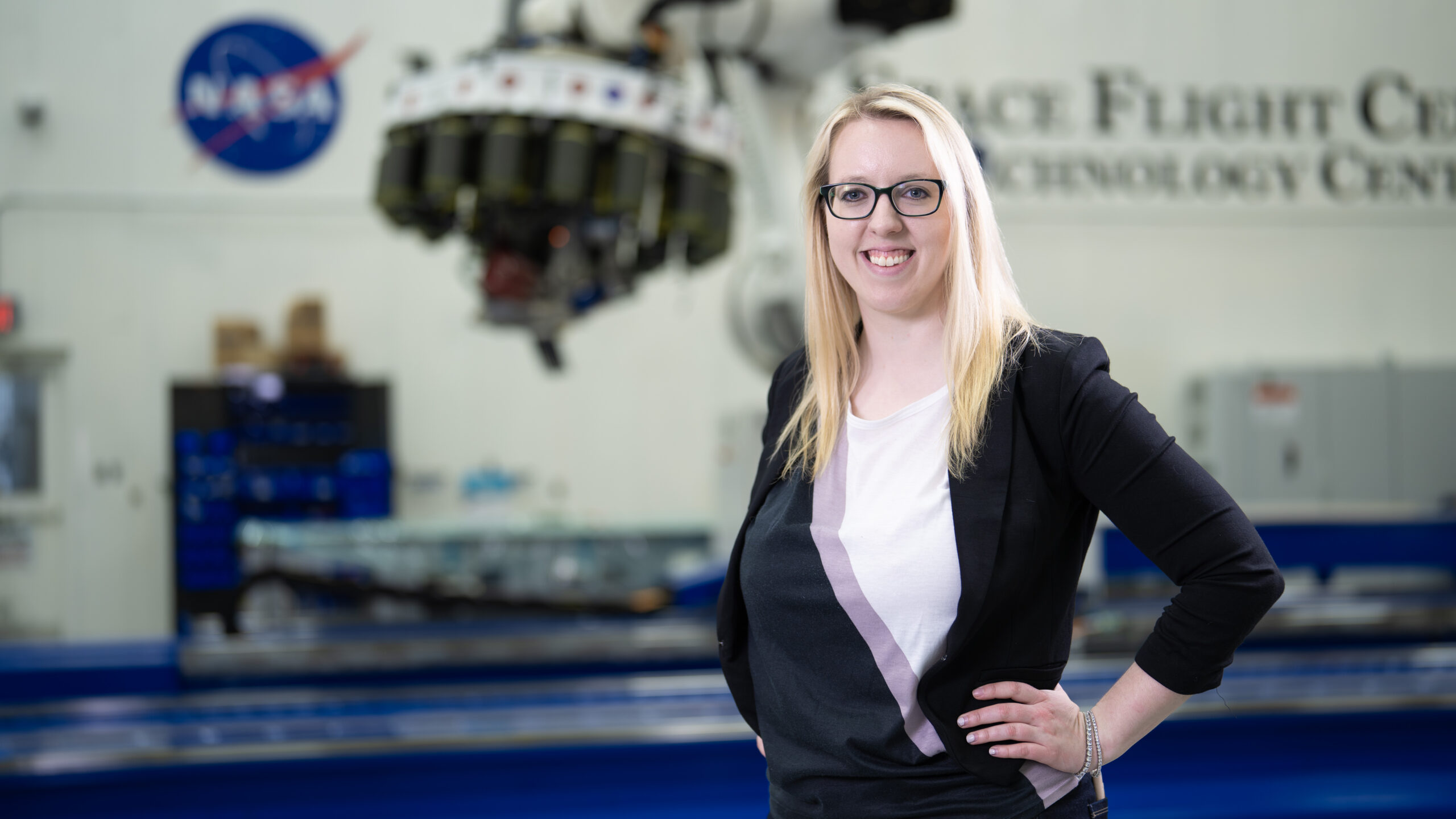

In the realm of space exploration, the creation of a Moon rocket demands more than just technical expertise, precision, and engineering skills. Casey Wolfe, the assistant branch chief of the advanced manufacturing branch at NASA’s Marshall Space Flight Center in Huntsville, Alabama, emphasizes that teamwork is a crucial aspect of this monumental task.

"Engineering is vital, but to get this type of work done, you need to take care of the human element," Wolfe remarked. This statement underscores the importance of collaboration among the diverse teams involved in NASA’s ambitious projects, such as the Space Launch System (SLS) super-heavy lift rocket.

Building the Next Generation Payload Adapter

Wolfe and her team are at the forefront of developing the next generation payload adapter for NASA’s SLS rocket. This adapter plays a critical role in ensuring that payloads are securely attached to the rocket as it embarks on its missions beyond Earth. The team employs some of the most advanced composite manufacturing techniques globally, which are essential for creating lightweight yet robust components for space missions.

In her role, Wolfe skillfully balances the technical operations with the management of personnel in the composites manufacturing and additive manufacturing teams. This involves overseeing the production of SLS hardware while simultaneously working on new engines using state-of-the-art manufacturing technologies.

"My day-to-day responsibilities involve managing our two teams, fostering connections, building relationships, and ensuring that everyone feels supported," Wolfe explained. She further noted that regular individual meetings with team members help in proactively addressing potential issues before they escalate.

A Journey from Huntsville to NASA

Hailing from Huntsville, a city affectionately known as "Rocket City," Wolfe’s journey to NASA was not initially a planned one. It wasn’t until she attended a job fair at Auburn University, where she was studying polymer and fiber engineering, that she began to consider a career at NASA Marshall. Her path led her to apply for and secure an internship through NASA’s Pathways Program, where she worked in the non-metallic materials branch of the Materials and Processes Laboratory.

During her internship, Wolfe contributed to a coating system designed for electrostatic discharge on the first uncrewed test flight of the Orion spacecraft. This mission, launched on December 5, 2014, saw Orion reach an altitude of 3,600 miles, orbit Earth twice, and then safely splash down in the Pacific Ocean. This experience was transformative for Wolfe, as she realized the significance of being an integral part of the NASA team.

"The SLS program gave everyone permission to sign the hardware, even me – even though I was just an intern," Wolfe recalled. "It was impactful to me, knowing that something I had worked on had my name on it and went to space."

Contributions to the Artemis Missions

Since joining NASA, Wolfe has played a vital role in the development of the Orion stage adapter diaphragms for Artemis II and Artemis III, as well as the payload adapters for Artemis IV and subsequent missions. The initial Artemis flights utilize the SLS Block 1 rocket variant, capable of sending over 27 metric tons (59,500 pounds) to the Moon in a single launch. However, starting with Artemis IV, the upgraded SLS Block 1B variant will come into play. This new variant, featuring a more powerful exploration upper stage, will enable more ambitious deep space missions, with the payload adapter sitting at the top of the rocket’s exploration upper stage. The SLS Block 1B will be capable of launching more than 38 metric tons (84,000 pounds) to the Moon in one go.

"While the engineering development unit of the payload adapter is undergoing large-scale testing, our team is focused on producing the qualification article, which will also undergo testing," Wolfe stated. "We anticipate starting fabrication of flight components within the next six months."

Balancing Work and Personal Life

Outside of her demanding work schedule, Wolfe enjoys hiking, gardening, and spending time with her dogs and large family. Recently, she had the privilege of signing another piece of SLS hardware destined for space: the Orion stage adapter for the second Artemis mission.

Despite her numerous responsibilities, Wolfe remains acutely aware of the impact of her work. "I work in the lab around the hardware all the time, and in many ways, it can become very rote," she admitted. However, a late-night encounter with two security guards taking pictures in front of the launch vehicle stage adapter served as a poignant reminder of the historical significance of her team’s contributions.

The Broader Impact of NASA’s Artemis Program

NASA is committed to making history with its Artemis program, which aims to land the first woman, the first person of color, and its first international partner astronaut on the Moon. The SLS rocket is a cornerstone of NASA’s deep space exploration initiatives, working in tandem with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in lunar orbit, and commercial human landing systems. The SLS is currently the only rocket capable of sending the Orion spacecraft, along with astronauts and supplies, to the Moon in a single launch.

The collaborative efforts of Wolfe and her colleagues at NASA’s Marshall Space Flight Center exemplify the dedication and teamwork required to push the boundaries of space exploration. As they continue to develop cutting-edge technologies and components, they are not only building rockets but also paving the way for humanity’s future in space.

For more information on NASA’s endeavors and the Artemis program, you can visit the NASA website.

For more Information, Refer to this article.