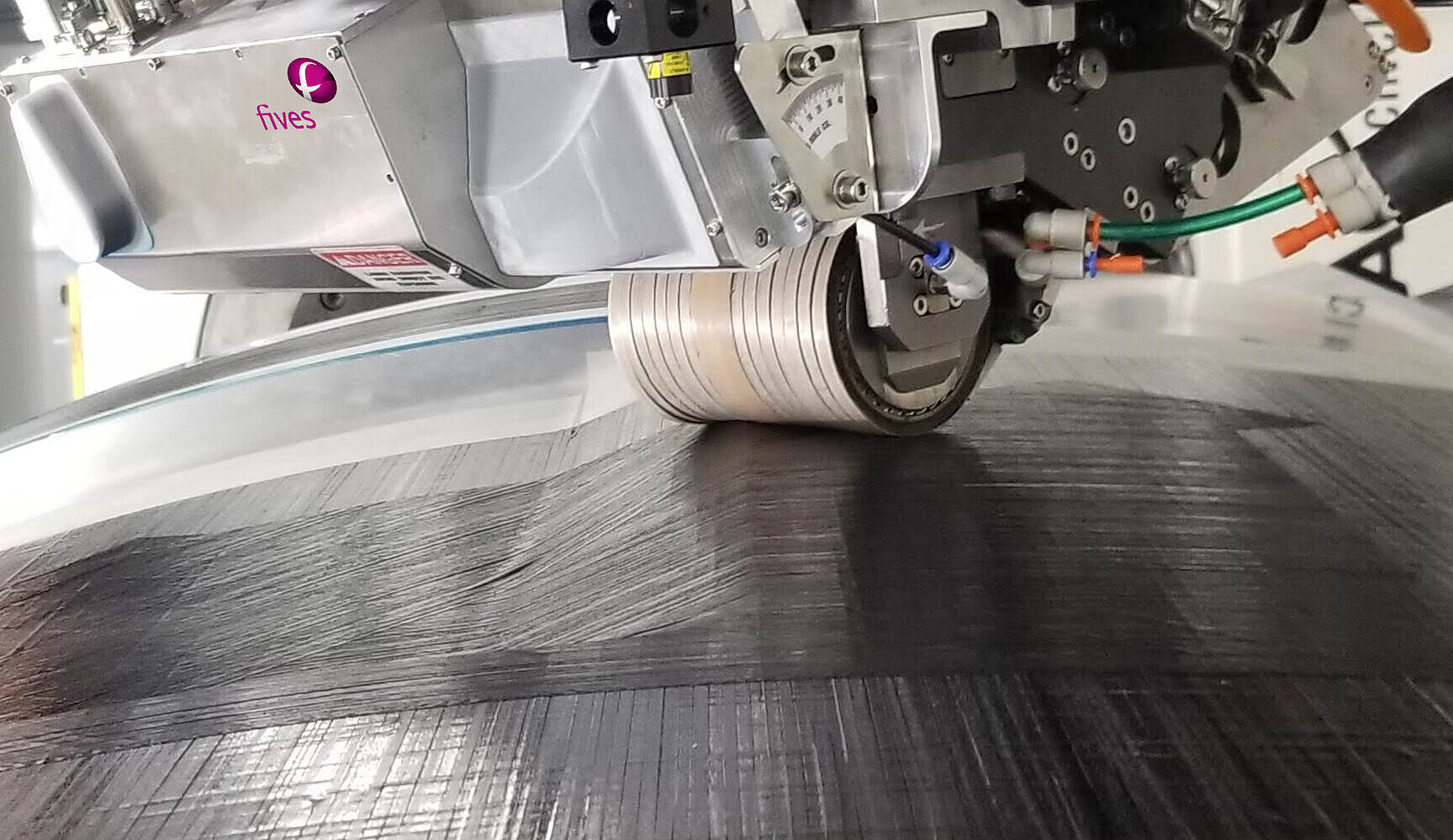

Gulfstream Aerospace Corporation and Fives Machining Systems Inc. Join NASA’s Hi-Rate Composite Aircraft Manufacturing Project

In an exciting development for the aerospace industry, Gulfstream Aerospace Corporation and Fives Machining Systems Inc. have joined a coalition of 20 other organizations to support NASA’s Hi-Rate Composite Aircraft Manufacturing (HiCAM) project. This initiative is geared towards meeting the increasing demands for air travel, replacing aging fleets of airliners, and ensuring that the United States remains competitive in the commercial aircraft industry.

Addressing Industry Needs

The HiCAM project is pivotal for the aerospace sector, as it aims to address several critical needs. First, with the global demand for air travel on the rise, there is an urgent requirement to ramp up the production of new aircraft. Additionally, many existing airliners are reaching the end of their operational lives and need to be replaced with more efficient and technologically advanced models. The project also aims to strengthen the U.S.’s standing in the competitive arena of commercial aircraft manufacturing.

A Collaborative Effort

NASA, along with its partners, is pooling resources and expertise to elevate the manufacturing rate of aircraft components made from composite materials. These materials are nonmetallic and offer several advantages over traditional metal counterparts, such as reduced weight and enhanced durability. Gulfstream and Fives are the newest members of the Advanced Composites Consortium, a public-private partnership that is driving this initiative forward.

Expertise and Innovation

Members of the Advanced Composites Consortium bring a wealth of knowledge and unique capabilities to the table. The consortium comprises organizations with significant expertise in various aspects of aircraft design, manufacturing, certification, testing, and tool development. The inclusion of Gulfstream and Fives adds new dimensions of insight and capability, enriching the collective knowledge pool.

Richard Young, the manager for NASA’s HiCAM project, expressed optimism about the consortium’s goals. “By partnering with U.S. industry, academia, and regulators, we’ll increase the likelihood of impacting the next generation of transports,” he said. This collaborative approach aims to foster innovation and accelerate the adoption of new technologies in the aerospace sector.

Technological Advancements

The consortium is currently evaluating various concepts to determine which technologies can most effectively increase manufacturing rates. This involves rigorous competition among different ideas, with the most promising ones being selected for full-scale demonstration. This methodical approach ensures that only the most viable and impactful technologies are pursued.

Environmental and Economic Benefits

The HiCAM project and the Advanced Composites Consortium are integral to NASA’s Sustainable Flight National Partnership. By enabling broader use of lightweight composite airframes, the initiative aims to significantly reduce fuel consumption and carbon emissions. This, in turn, will improve air quality and contribute to environmental sustainability.

Composite materials, due to their lightweight nature, can drastically reduce the overall weight of aircraft. This reduction in weight leads to lower fuel consumption, which not only cuts operational costs for airlines but also results in fewer carbon emissions. In an era where environmental concerns are paramount, such advancements are crucial for the future of air travel.

Managed by NASA’s Advanced Air Vehicles Program

The HiCAM project is managed under NASA’s Advanced Air Vehicles Program, which is dedicated to developing and implementing cutting-edge technologies for the next generation of aircraft. This program aims to revolutionize air travel by making it more efficient, sustainable, and safe.

The Importance of Composite Materials

To understand the significance of the HiCAM project, it is essential to grasp the benefits of composite materials. Unlike traditional metals, composite materials are made from two or more constituent materials with different physical or chemical properties. These materials are combined to produce a material with characteristics different from the individual components.

In the context of aircraft manufacturing, composites offer several advantages:

- Lightweight: Composite materials are significantly lighter than metals, which helps reduce the overall weight of the aircraft. This leads to lower fuel consumption and operational costs.

- Strength and Durability: Despite being lightweight, composite materials can be incredibly strong and durable. They are resistant to corrosion and fatigue, which enhances the longevity of the aircraft.

- Design Flexibility: Composites can be molded into complex shapes, providing greater design flexibility. This allows for more aerodynamic designs, which can improve fuel efficiency.

- Reduction in Maintenance: The durability and resistance to corrosion of composite materials mean that aircraft require less maintenance, reducing downtime and costs for airlines.

Industry Reactions and Reviews

The inclusion of Gulfstream and Fives in the HiCAM project has been met with positive reactions from industry experts. Gulfstream is renowned for its high-performance business jets, and its expertise in aircraft design and manufacturing is expected to be a valuable addition to the consortium. Fives Machining Systems, with its advanced machining technologies, will bring critical capabilities to the manufacturing process.

Industry analysts believe that the HiCAM project has the potential to revolutionize the aerospace sector. By accelerating the adoption of composite materials, the project could lead to the development of more efficient and environmentally friendly aircraft. This would not only benefit airlines by reducing operational costs but also contribute to global efforts to combat climate change.

Conclusion

The collaboration between NASA, Gulfstream Aerospace Corporation, Fives Machining Systems Inc., and other consortium members marks a significant step forward in the aerospace industry. The HiCAM project is poised to address the growing demand for air travel, replace aging fleets, and ensure that the U.S. remains at the forefront of commercial aircraft manufacturing.

By leveraging the expertise and resources of its members, the Advanced Composites Consortium aims to increase the manufacturing rate of aircraft components made from composite materials. This will enable the broader use of lightweight composite airframes, leading to reduced fuel consumption and carbon emissions.

As the project progresses, it will be exciting to see how the selected technologies are demonstrated at full scale and their impact on the aerospace industry. The HiCAM project exemplifies the power of collaboration between industry, academia, and regulators in driving innovation and shaping the future of air travel.

For more Information, Refer to this article.