Innovative Product Design with nTop: A Leap Towards Future Engineering

Understanding the transformative impact of digital tools on product design is crucial in today’s fast-paced engineering landscape. Bradley Rothenberg, a visionary in the field, turned his fascination with computer-aided design (CAD) software into a groundbreaking startup known as nTop. This company is redefining how product developers across various industries create and iterate designs, pushing the boundaries of traditional engineering with cutting-edge technology.

The Origins of nTop

Bradley Rothenberg’s journey began with an intense interest in CAD during his teenage years. By the time he was in his twenties, he had harnessed this passion to establish nTop, a company that provides developers with advanced tools to model and create innovative designs. What sets nTop apart is its focus on iteration and innovation in design, two elements that are often intertwined in achieving breakthrough developments.

The Power of GPU-Based Engineering

A significant insight from Rothenberg was recognizing the potential of using Graphics Processing Units (GPUs) instead of Central Processing Units (CPUs) for engineering software. Traditionally, CPUs have been the backbone of CAD tools. However, by leveraging the parallel processing capabilities of GPUs, nTop can offer designers rapid and almost limitless iterations for any given project. This shift unlocks boundless opportunities for innovation, enabling designers to explore and refine their ideas with unprecedented speed.

A Decade of Growth and Innovation

Since its inception, nTop has grown into a thriving enterprise, employing over 100 professionals primarily based in New York City, with additional presence in Germany, France, and the U.K. The company is part of the NVIDIA Inception program, which supports startups at the forefront of technological advancement. With plans to expand by another 10% by the end of the year, nTop is poised to continue its trajectory of growth and innovation.

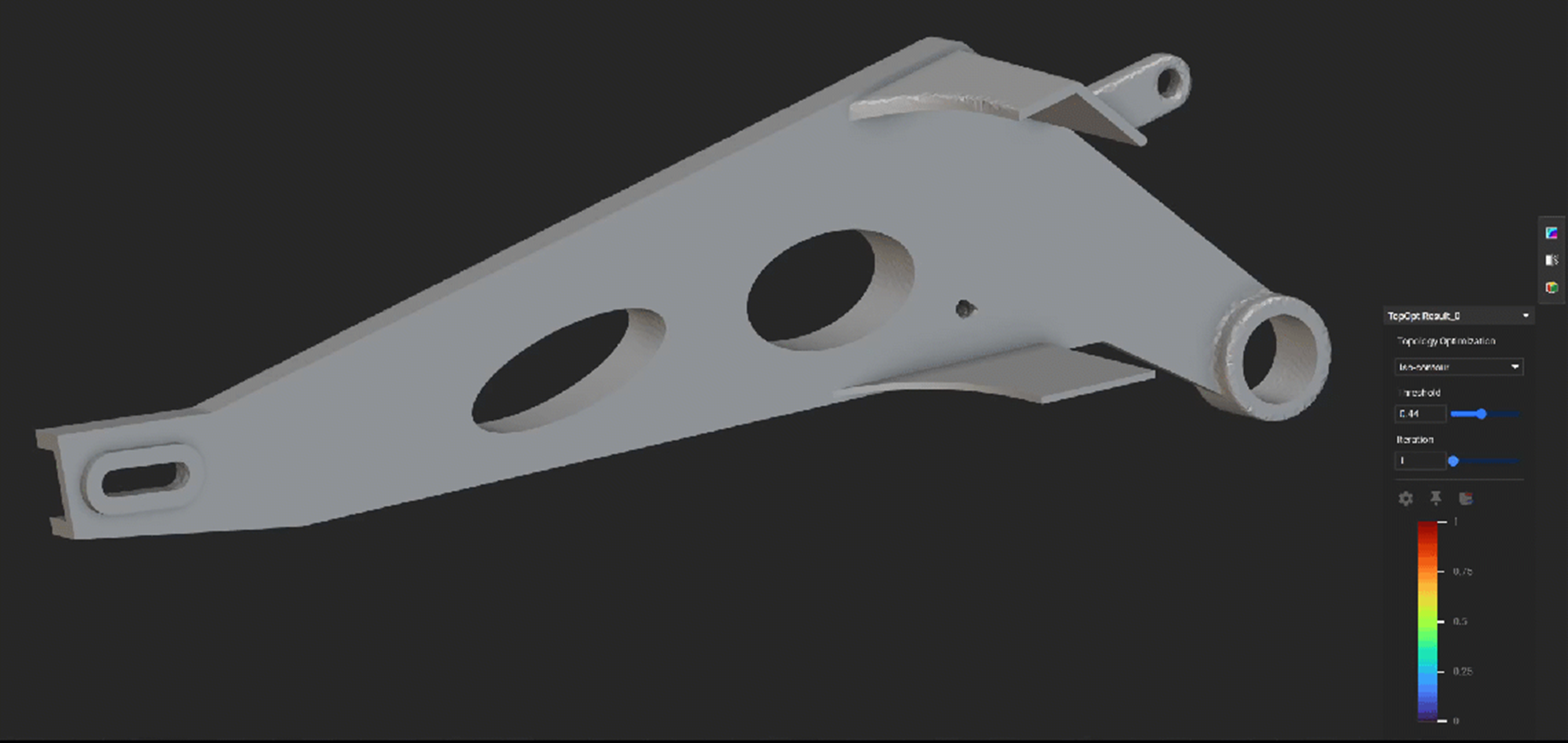

Transformative Design Tools

nTop’s computational design tools are revolutionizing the way designers work. These tools autonomously iterate alongside designers, generating different virtual shapes and testing potential materials to produce high-performance products. This process of design trial and error at scale allows for rapid experimentation and optimization.

For designers, this means they can quickly evaluate the impact of changes on a design’s performance. As Rothenberg explains, designers often grapple with competing goals and questions, such as how a change might affect weight or thickness. nTop’s tools help address these concerns in real time, providing immediate feedback on performance changes.

A Case Study: Ocado’s Robotic Revolution

One of nTop’s most notable success stories is its collaboration with Ocado, a U.K.-based supermarket chain known for its integration of autonomous robots in grocery picking and warehouse operations. Ocado’s robots, the size of office chairs, navigate massive warehouses at high speeds, performing tasks with millimeter precision.

In their early designs, these robots faced issues with breakdowns and even fires, partly due to their weight, which necessitated more expensive and robust warehouse construction. nTop’s software enabled Ocado’s robotics team to redesign 16 critical robot parts, reducing the robot’s weight by two-thirds. Remarkably, this redesign process took just a week, compared to the four months required without nTop’s tools.

Advanced Prototyping and Testing

Ocado’s redesigned robots were prototyped using 3D printing technology, allowing for quick-turn testing. This approach significantly reduced costs and improved the durability of the robots, showcasing how nTop’s tools can lead to more efficient and cost-effective solutions.

The Role of AI and Simulation

nTop is also at the forefront of integrating artificial intelligence into its design processes. By incorporating AI models into its simulation workloads, nTop can utilize bespoke design data from customers to enhance the iteration process. The company employs NVIDIA’s Modulus framework, Omniverse platform, and CUDA-X libraries to train and execute these advanced computing workloads.

This integration of AI allows for the rapid training of neural networks on a company’s specific design data, enabling quick iterations through different versions of a product. For example, a company can use nTop to design a car structure, train an AI on this data, and swiftly iterate new versions of the car or future designs.

Broader Industry Applications

nTop’s tools are being used across a wide range of industries. For instance, a Formula 1 design team utilized nTop to model various versions of heat sinks. The result was an unconventional yet highly effective design that significantly improved cooling performance while reducing weight.

Traditionally, heat sinks consist of uniform metal pieces designed to maximize heat exchange. However, with nTop, engineers developed a multilevel sink that optimized both air-metal interaction and aerodynamics, critical for racing success. This new design achieved three times the surface area for heat transfer compared to previous models and reduced weight by 25%.

The Future of Implicit Modeling

Looking ahead, nTop anticipates increased adoption of its implicit modeling tools among product designers seeking an iterative partner trained on their company’s proprietary data. This approach allows designers to run multiple simulations and optimize designs for the best results, paving the way for continued advancements in product design.

In summary, nTop is revolutionizing the field of product design with its innovative tools and AI integration. By enabling rapid iteration and optimization, nTop empowers designers to push the limits of creativity and efficiency. As the company continues to grow and evolve, it promises to drive further advancements across industries, shaping the future of engineering and design.

For more details, you can explore nTop’s product design workflow and its collaborations with partners in various industries.

For more Information, Refer to this article.